R&D LAB

Technological &

Tailored Solutions

FUSÃO’s expertise is built on years of on-the-ground experience in sourcing, developing, and assembling technical textile materials in Europe and Asia.

FUSÃO relies on its workshop in Lisbon and its international network of specialised partners to provide tailored services and competitive solutions to meet customers’ requirements.

OUR TAILORED R&D SERVICES

SOURCING &

DEVELOPMENT

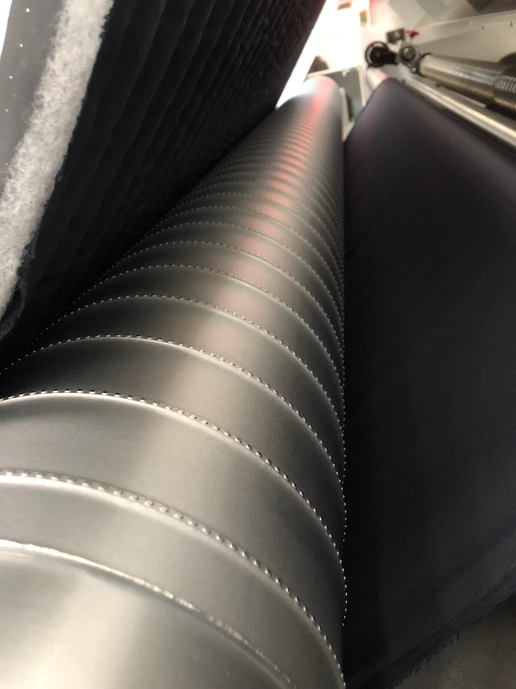

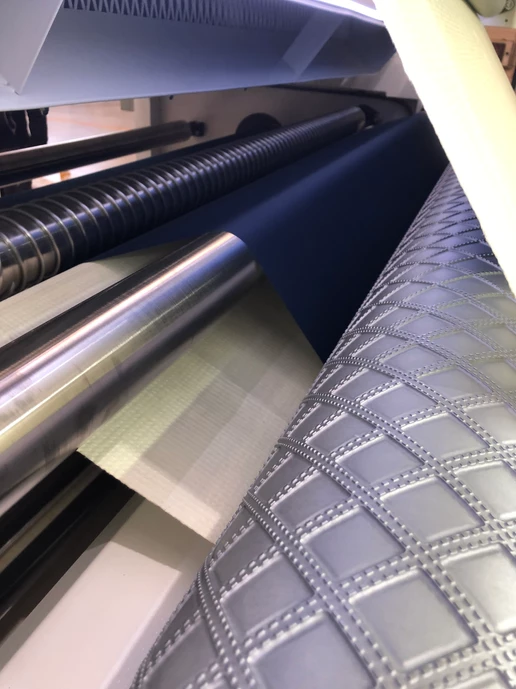

FUSÃO works closely with manufacturers and brands on their projects, advising on technical options, and elaborating unique materials for demanding specifications.

FUSÃO elaborates responses through an approach that is tailored to each specific challenges and needs.

FUSÃO provides supports through its research and development workshop in Lisbon enabling to study, test and develop the most effective solutions – whilst ensuring the utmost confidentiality.

TAILORED SERVICES

TEXTILE IS TECHNOLOGICAL

OUR TECHNICAL SOLUTIONS

UNIQUE &

MULTI-FUNCTIONAL

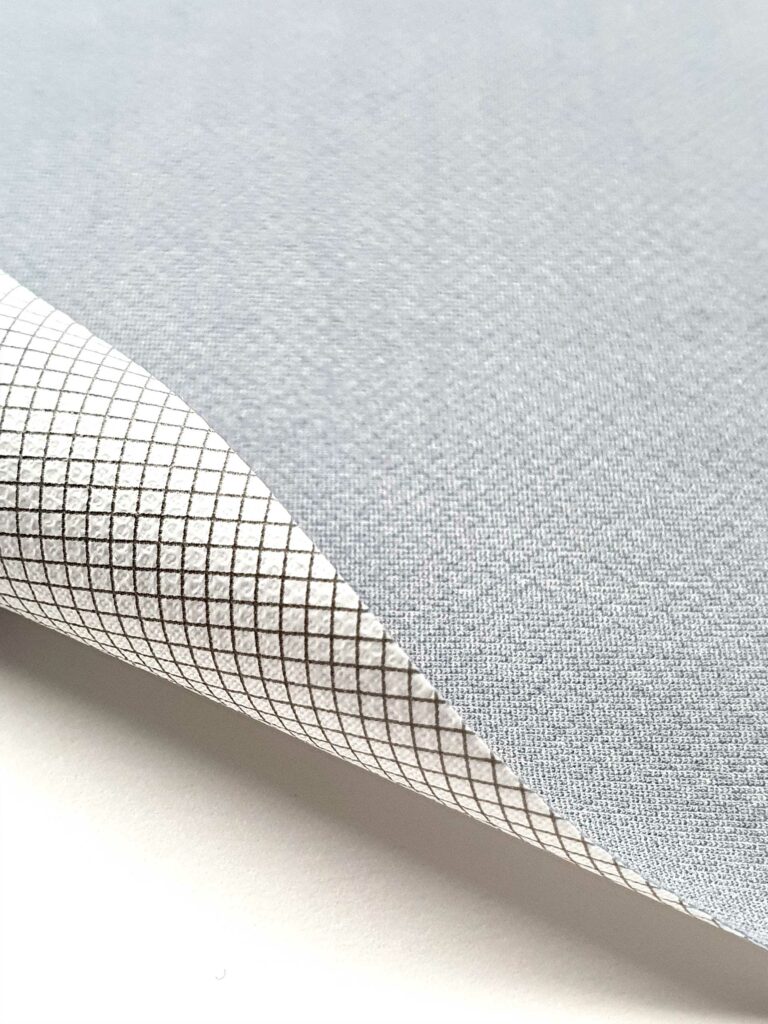

FUSÃO‘s solutions are always designed with an appropriate supply of fabrics and assembly to create high-performance materials.

MATERIALS

knitting fabrics l woven fabrics l non-woven l lace & embroidery l wadding l foam l membrane l web l net l laminated fabrics l coated l ultrasonic welded l padded fabrics

PERFORMANCES

water-repellent l windbreak l anti-perforation l breathable l waterproof l anti-abrasion l UV protection l high visibility l anti-bacteria l high filtration l air permeability l comfort l super light & nomad l high support & compression l fireproof l sound insulation l thermal insulation

OUR TAILORED R&D SERVICES

QUALITY TESTS

FUSÃO is specialized in developing technical materials using specific fabrics to meet high-performance requirements for a demanding market. FUSÃO offers its expertise for customized solutions from fibers to final products.

FUSÃO and its partners are equipped with a quality laboratory.

All selected materials are inspected and tested to check it is matching with customer requirements.

The aspect, width, weight, thickness, elongation, stability, finishing are checked before processing.

Once finished, the below quality tests can be performed on the multi-layers products.

PEELING STRENGHT (ISO 8510-2:2006) – Peel test for a flexible-bonded-to-rigid test specimen assembly

ELONGATION (ISO 13937-1:2000) – Tear properties of fabrics

WASHING & DRYING (ISO 6330:2012) – Domestic washing and drying procedures for textile testing

SHRINKAGE (ISO 5077:2007) – Determination of dimensional change in washing and drying

SPRAY TEST (ISO 4920:2012) – Determination of resistance to surface wetting (spray test)

WATERPROOFNESS (ISO 811:2018) – Control the waterproof performance of materials

RET (ISO 11092:2014) – Measurement of water-vapour resistance under steady-state conditions

RCT (ISO 11092:2014) – Measurement of thermal under steady-state conditions

AIR PERMEABILITY (ISO 9237:1995) – Determination of the permeability of fabrics to air

ABRASION (ISO 12947-2:2016) – Determination of the abrasion resistance of fabrics

PILLING (ISO 12945-2:2020) – Determination of fabric propensity to surface pilling, fuzzing or matting

BURSTING STRENGHT (ISO 13938.1:1999) – Bursting properties of fabrics

QUALITY IS A PRIORITY

FUSÃO ensure that all items developed and produced with its partner matched with the required quality and performances of customers

TECHNOLOGICAL & TAILORED SOLUTIONS

DISCOVER OUR FABRICS

Prev

Next